Laser Cleaning of Stainless Steel: Everything You Need to Know

Stainless steel has a wide range of uses. It is needed in kitchens, workshops, or factories. It is also common for hospitals to use stainless steel parts because of their corrosion resistance. However, stainless steel parts can get dirty for a variety of reasons. Whatever the reason, it is crucial to choose the right cleaning method. Laser cleaning of stainless steel is one of the popular methods in this case.

Stainless steel contains chromium in its chemical structure. This chromium usually forms a chromium oxide layer on the surface, which acts as a corrosion protection. This is why stainless steel is used in many applications. But it still corrodes, especially in salty water such as seawater. Stainless steel parts of ships can corrode due to these extreme conditions.

In addition, stainless steel parts during the manufacturing process can pick up dirt or oil over time. In the medical industry, stainless steel parts need to be sterilized before each operation.

Laser cleaning is ideal for a variety of reasons. This article will explain these advantages, especially by discussing its various uses. This will help you understand the importance of using lasers to clean stainless steel.

What is Laser Cleaning of Stainless Steel?

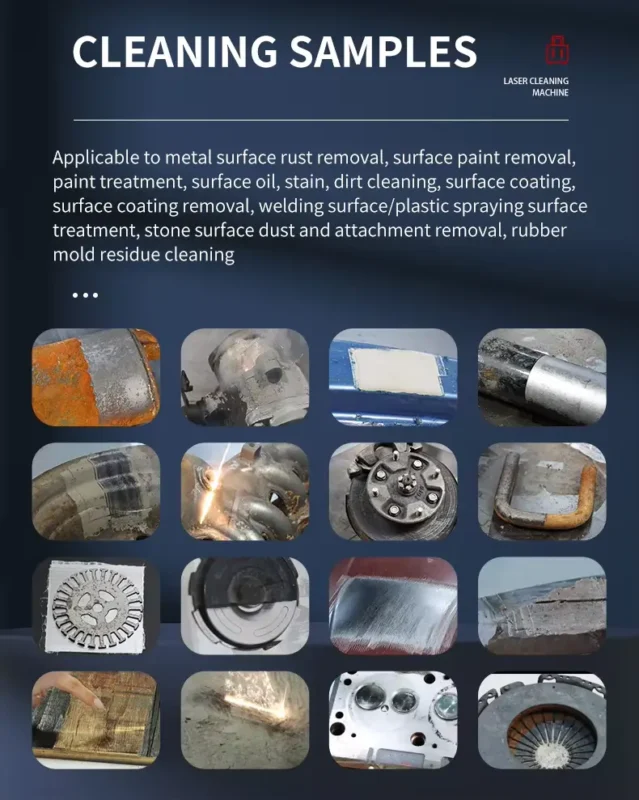

Laser cleaning of stainless steel removes contaminants, corrosion and coatings. Its purpose is similar to other cleaning methods, but the media is different. Abrasive blasting uses sand, dry blasting uses dry ice, and chemical cleaning uses chemicals. Laser cleaning uses a highly focused laser beam.

Laser cleaning of stainless steel uses a concentrated laser beam to remove dirt from stainless steel. High-energy laser pulses hit the stainless steel, heating and breaking down unwanted particles on its surface. These particles then evaporate, revealing clean, bright metal underneath. This method is fast, efficient, and very effective.

The biggest advantage of laser cleaning is its versatility. You can clean everything from tiny electronic parts to large industrial machinery. Accuracy is another advantage. This tool removes only the parts that need to be removed, leaving the rest intact. So if you need to restore the shine to a part or prepare it for welding, laser cleaning is the best choice.

Effects of laser cleaning on stainless steel

Laser cleaning other metals and stainless steel is very different. The main reason behind this is the presence of chromium. Stainless steel usually has a protective oxide layer because it contains chromium. This chromium oxide film is naturally shiny and does not rust.

This reflective property changes the way lasers work when cleaning stainless steel. Therefore, laser settings for stainless steel need to be carefully monitored and set correctly. When the focused laser beam hits the material, the area quickly encounters a sudden temperature increase. It quickly melts and evaporates the contaminants. When the laser moves to the next position, the same thing happens again. In this way, the stainless steel is cleaned.

Due to the shiny surface of stainless steel, laser settings are crucial. Today, most laser cleaners have the option to work independently. The cleaning process is the same, but the correct laser settings must be selected before cleaning.

Common uses for laser cleaning of stainless steel

Laser cleaning is widely popular in many fields. Modern people prefer this method over other older methods. This huge demand is especially evident in work, medical, and manufacturing industries. Laser cleaning is the best method for cleaning stainless steel. In this section, you will learn about some common uses of this method.

Laser removal of oxides from stainless steel welds

Welding stainless steel joints usually forms a layer of oxide. This is quite normal. However, if it is not treated, several problems may occur. For example, you will see corrosion or a weakened weld. In this case, laser cleaning of stainless steel can be of great help.

Laser cleaning machines can effectively remove laser oxide from stainless steel weld joints. You can only clean the laser oxide layer without damaging the parent material. Technically, you will not find this feature in other cleaning technologies. There are several benefits to removing laser oxide from stainless steel weld joints.

(1) Laser cleaning maintains the strength and appearance of the weld of the stainless steel part. It is a non-contact process and will not affect the quality of the weld.

(2) Laser cleaning of stainless steel is precise and controllable. The best part is that you can change the laser settings according to the different oxide layers. This precision usually reduces the risk of damaging the base material.

(3) Laser removal of oxide from stainless steel welds improves weld quality and overall weld quality. Therefore, people in the automotive industry like to use laser cleaning of stainless steel.

(4) Laser cleaning of stainless steel always provides consistent oxide removal results. You don’t have to worry about further cleaning.

(5) Laser oxide removal produces a clean, polished surface on the weld joint. Therefore, you can be sure that your stainless steel parts will look great.

Laser paint removal on stainless steel parts

Even though stainless steel won’t rust, it can still happen. It usually happens under extreme conditions. The best example is the marine environment. As you know, salt water and moisture are common conditions. Stainless steel parts that come into contact with these things will rust over time.

Paint can usually protect the surface of stainless steel and keep it looking beautiful. However, you may need to remove the paint or prepare to repaint.

There are many ways to remove paint, but the key is to choose the best method. In the past, people used grinding or chemicals to clean stainless steel parts. These methods were usually messy and required a lot of work. In the modern world, things have changed. Laser cleaning, which emerged in the 20th century, provides fast, safe, and accurate cleaning.

The laser paint removal process is the same as other cleaning methods. A focused laser beam hits the surface of the material and evaporates the paint. During the whole process, it does not affect the stainless steel underneath. This procedure is very effective for removing previous paint coatings.

Laser cleaning does not produce waste or emit toxic chemicals. Therefore, it can be said that laser cleaning is an environmentally friendly method. One of the best parts of laser cleaning stainless steel is its ability to clean complex metal parts. Therefore, all complex stainless steel parts can be cleaned with laser cleaning.

Pretreatment for coating or welding

Pretreatment is a key process before stainless steel coating. This process is usually used to prepare the surface for stainless steel coating. It is well known that contaminants on the surface may affect the quality and durability of the coating. Therefore, the pretreatment process must be considered.

You can use the laser cleaning method for stainless steel to do this job. Laser cleaning uses a highly focused laser beam to irradiate the surface of the material to melt and evaporate contaminants. Then, it leaves the surface of your stainless steel parts intact. This pre-treated surface can often improve coating adhesion or welding quality.

It is well known that stainless steel has a bright and shiny appearance and is extremely corrosion-resistant. This means that this metal can reflect part of the laser energy. If your laser wavelength is not suitable, you may not get the best results. Therefore, when cleaning stainless steel parts, always stick to the appropriate laser frequency. You can ask professionals for help.

Stainless steel laser rust removal

As mentioned above, stainless steel has excellent corrosion resistance. Because of this, it is widely used in food processing, medical and automotive parts. However, it still faces problems in harsh environments.

After all, rust is the enemy of any metal. Rust on stainless steel can sometimes be difficult to deal with. Traditional methods such as sandblasting or grinding do not provide the best results. You can also try chemical cleaning, but this is not environmentally friendly.

In this case, laser rust removal is the most suitable method. It is practical and does not harm the underlying parent material or the environment.

Laser cleaning machines are usually designed to remove rust layer by layer. If the rust is thicker than usual, you may need to clean it more than once. When you use a laser to clean stainless steel, the rust is vaporized and you are left with clean, corrosion-free stainless steel.

The biggest advantage of laser cleaning stainless steel is that no chemicals are required, so no waste or abrasive materials are generated. This method is widely used in the construction, shipping, and marine industries.

Laser cleaning is suitable for cleaning all kinds of equipment

Stainless steel is used to make many medical and industrial tools and machines. These tools and machines can accumulate dust or oil over time, which can cause many problems. Therefore, they must be cleaned regularly. In hospitals, every piece of medical equipment must be cleaned before operation. The old-fashioned method takes a long time and does not produce good results.

Laser cleaning of stainless steel allows you to clean faster and more efficiently. This method is ideal for cleaning various residues, oils or chemicals.

(1) Some stainless steel equipment may be thin and fragile. Sandblasting or grinding are not suitable options. Chemical cleaning is troublesome and not environmentally friendly. Laser cleaning of stainless steel is the best choice in this case.

(2) Lasers can reach any surface, even those with complex shapes. Using laser cleaning allows you to use equipment and tools of various sizes and designs.

(3) Laser cleaning of stainless steel does not require additional labor. Therefore, you can save a lot of project investment.

(4) Since laser cleaning does not require consumables, the operating cost is low. Although the initial cost may be higher, you can enjoy a cost-effective solution in the long run.

Please contact us!

BOGONG CNC is a leading manufacturer of various laser cleaning equipment. You can choose various models of laser cleaning stainless steel equipment from our store. If you have any questions, please feel free to contact our customer service