Advantages and Disadvantages of Laser Cleaning Machines

As science and technology continue to evolve, we have witnessed the profound impact of technological advancements on various aspects of life. The relentless innovation and development in these fields have enabled us to accomplish a significant amount of work quickly, efficiently, at lower costs, and with minimal environmental impact. Among the many emerging technologies, laser cleaning machines have emerged as an important and rapidly advancing field.

With the diverse work needs across industries, laser cleaning machines have gradually become a preferred choice, replacing traditional cleaning methods. As a high-speed, efficient, and eco-friendly cleaning solution, laser cleaning machines are gaining widespread adoption.

Here, we are pleased to introduce the advantages of BOGONGCNC’s laser cleaning machines. Firstly, these are professional-grade cleaning tools. The latest laser technology from BOGONG CNC can be customized to meet the unique requirements of our customers, ensuring that their specific cleaning needs are addressed effectively.

Many of our customers may be encountering laser cleaning machines for the first time. At BOGONG CNC, we are committed to helping you understand the capabilities of our laser cleaning machines and to assist you in selecting the most suitable solution that can meet your needs and contribute to the growth and development of your business.

This article will provide a simple and easy-to-understand introduction to the working principle of BOGONG CNC’s laser cleaning machines, the advantages and disadvantages of laser cleaning, as well as the suitable applications of this technology.

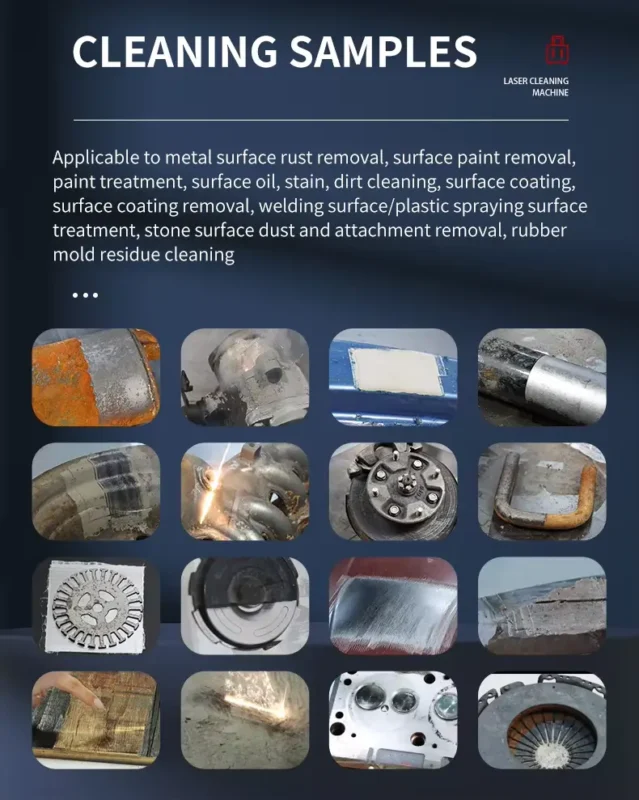

Since the emergence of lasers, laser technology has been applied to various industries and continues to evolve. Most traditional cleaning methods require the use of some media to achieve the desired cleaning effect, often resulting in the potential for surface damage to the material being cleaned. To overcome these limitations and achieve better cleaning results, laser cleaning technology has emerged as a viable solution.

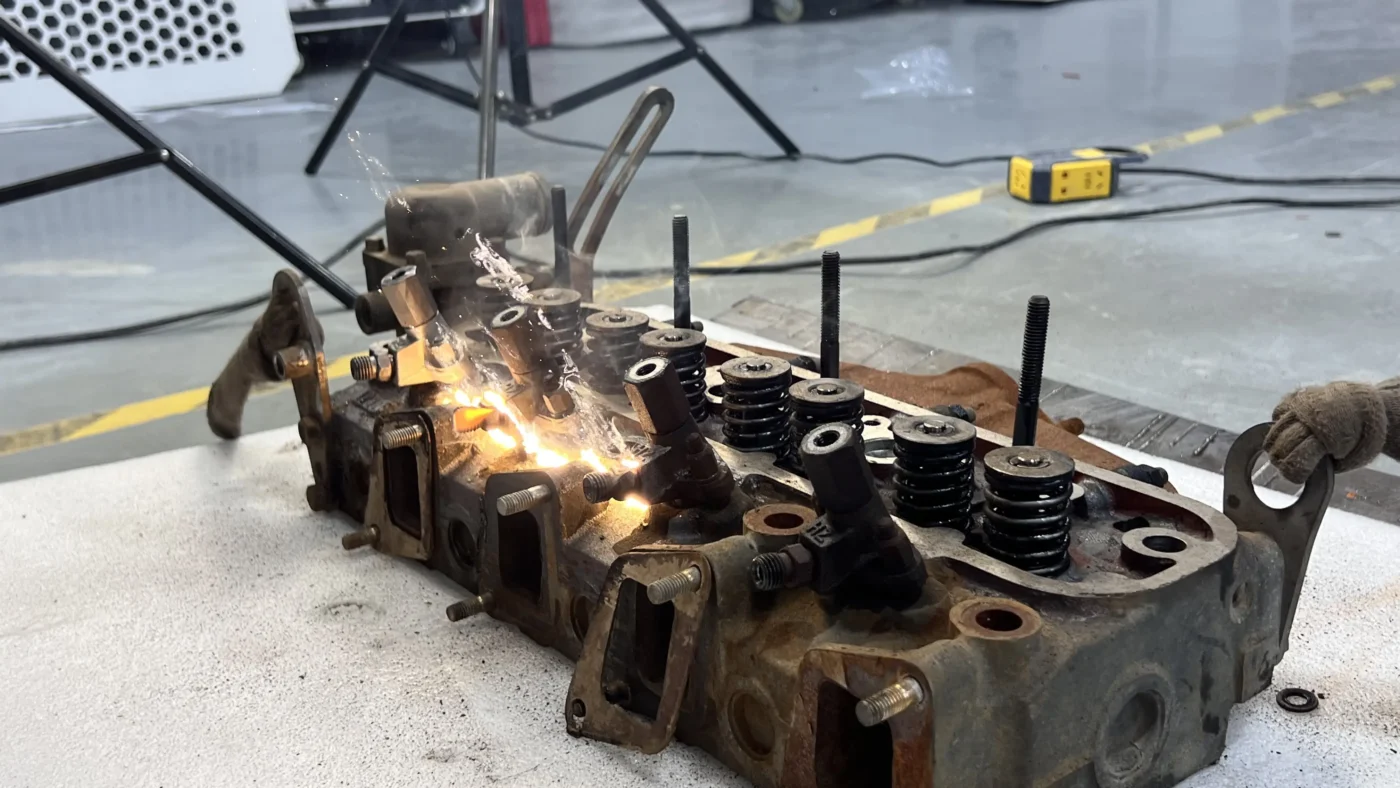

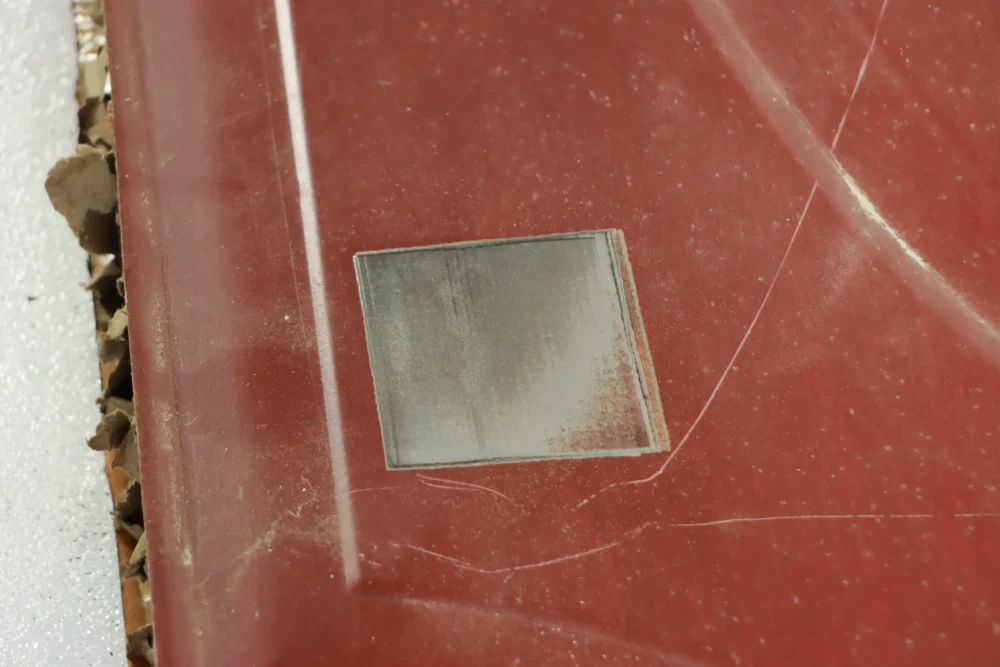

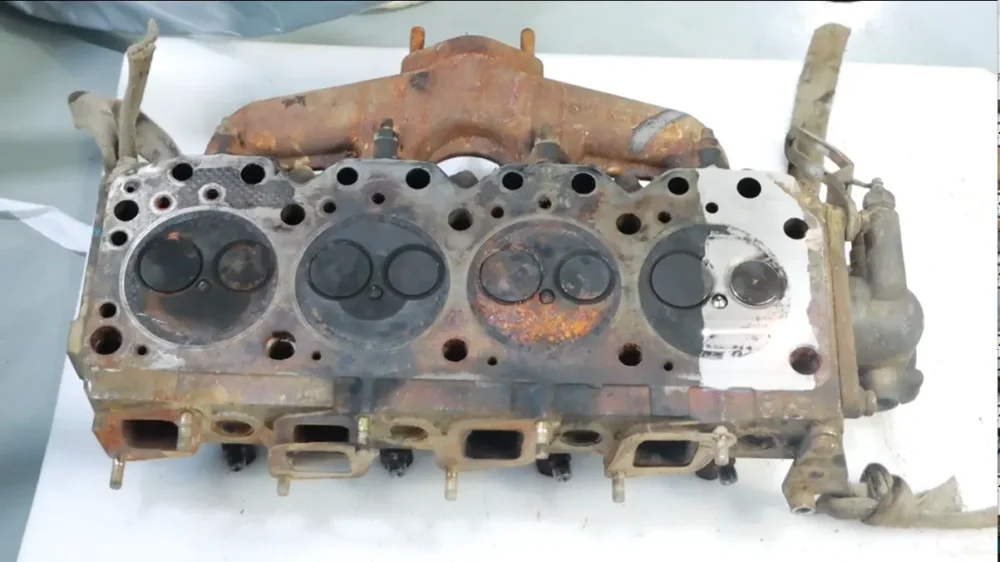

Laser cleaning is an advanced and outstanding material surface cleaning technology. BOGONG CNC’s laser cleaning machines utilize the high heat of the laser to evaporate paint, rust, or dirt on the surface of the material being cleaned. This process is achieved without the need for any additional media or chemicals, making it a simple and efficient cleaning method that can replace most traditional cleaning approaches.

BOGONG CNC’s laser cleaning machines can be categorized into two main types: pulse laser cleaning machines and continuous laser cleaning machines. Each of these machine types has its own unique advantages and disadvantages, offering customers a range of options to suit their specific cleaning requirements.

Advantages of BOGONGCNC’s Laser Cleaning Machines:

1.Suitable for Cleaning Precision Parts with No Damage:

BOGONGCNC’s laser cleaning machines can precisely adjust the cleaning width to achieve meticulous surface cleaning. The pulse laser cleaning machines, in particular, can not only complete thorough cleaning but also leave virtually no traces on the surface of the material. This makes BOGONGCNC’s pulse laser cleaning machines highly suitable for cleaning precision parts, cultural relics, or any other objects that have strict requirements on the surface condition of the material.

2.Non-Contact Cleaning:

BOGONGCNC’s laser cleaning machine utilizes a handheld laser cleaning head. During the cleaning process, the interaction between the laser cleaning machine and the materials being cleaned is entirely non-contact. This not only ensures the safety of the operator but also reduces wear and tear on the laser cleaning head, thereby improving its service life and cleaning efficiency. The non-contact cleaning method also helps to eliminate the impact of human factors on the cleaning quality.

3.Multiple Cleaning Modes:

BOGONGCNC’s pulse laser cleaning machine offers a variety of cleaning modes. Operators can easily switch between different cleaning modes by selecting the desired scan mode option on the operation interface. This versatility allows BOGONGCNC’s pulse laser cleaning machine to be used for cleaning materials of different shapes and surfaces, enabling efficient and effective cleaning across a wide range of applications.

4.High Speed and High Efficiency:

BOGONGCNC’s laser cleaning process utilizes the power of lasers to achieve the desired cleaning results. Compared to most traditional cleaning methods, laser cleaning offers the advantages of high speed and high efficiency. While many customers may assume that higher laser cleaning power equates to faster cleaning speed and better results, BOGONGCNC’s experienced engineers will recommend the most suitable machine based on the customer’s specific needs to ensure optimal performance.

5.Chemical-Free, Environmentally Friendly Cleaning:

Most traditional cleaning methods require the use of various chemicals or cleaning media, which often result in a significant amount of waste and pollution after the cleaning process. However, BOGONGCNC’s laser cleaning machines do not utilize any chemicals, thereby eliminating the generation of waste and reducing the cost of consumables. This makes BOGONGCNC’s laser cleaning machines an environmentally friendly cleaning solution, well-suited for long-term sustainable use.

6.Labor Cost Savings:

Operating BOGONGCNC’s pulse laser cleaning machine is a straightforward process that does not require specialized operator training or certifications. The machine features a user-friendly display interface, allowing the operator to easily adjust parameters such as laser power, frequency, scanning speed, number of scans, and scanning range (width and height). This intuitive control enables the operator to accurately manage the laser output, preventing substrate deformation due to excessive temperature and ensuring the surface of the material is not damaged, thereby achieving different cleaning effects on various materials. As a result, BOGONGCNC’s laser cleaning machines can help factories reduce labor costs.

7.Safe and Easy to Operate:

BOGONGCNC’s laser cleaning machines are designed to be safe and easy to operate. The machines can adapt to a wide range of complex working environments. Under normal use, the laser component has an impressive service life of up to 100,000 hours. BOGONGCNC’s laser cleaning machines offer an efficient and fast cleaning process, which can help factories improve their production efficiency and ultimately generate greater profitability.

8.Versatile Material Compatibility and Broad Industrial Applications:

BOGONGCNC’s laser cleaning machines can be applied to a diverse range of materials. These machines are capable of removing various surface impurities, such as oil stains, paints, oxides, rust, and coatings, making them suitable for a wide variety of industrial applications.

Disadvantages of Laser Cleaning Machines:

1.Higher Initial Investment:

The acquisition cost of a laser cleaning machine is typically higher compared to traditional cleaning equipment. The initial investment required for a laser cleaning system can be a significant barrier, especially for small to medium-sized businesses.

2.Pulse Laser Machines are More Expensive:

Within the category of laser cleaning machines, pulse laser models are generally more expensive than continuous wave laser machines. The specialized technology and components required for pulse laser systems contribute to their higher price point.

3.Safety Considerations:

Laser cleaning machines utilize high-energy laser beams, which can pose safety risks if not handled properly. Operators are required to wear appropriate personal protective equipment, such as laser-proof goggles, to prevent eye exposure to the intense light. Improper use or lack of safety precautions can lead to potential hazards.

4.Maintenance and Expertise:

Laser cleaning machines require specialized maintenance and technical expertise. Regular calibration, alignment, and component replacements are necessary to ensure optimal performance and safety. Hiring trained personnel or relying on manufacturer support can add to the overall operating costs.

5.Limited Cleaning Depth:

Laser cleaning is primarily effective for surface-level cleaning, removing contaminants, coatings, or oxides. It may have limitations in cleaning deeply embedded or stubborn deposits, which may require additional pre-treatment or the use of complementary cleaning methods.

6.Potential Substrate Damage:

If not carefully controlled, the high-energy laser beam can potentially damage or deform the substrate material being cleaned. Operators must exercise caution in selecting appropriate laser parameters to avoid causing unintended damage to the workpiece.

BOGONGCNC: A Leader in Laser Cleaning Technology

BOGONGCNC is a professional laser cleaning machine manufacturer with over 13 years of experience in designing and manufacturing high-performance laser rust removal machines. As a industry leader, BOGONGCNC offers a comprehensive range of laser cleaners, ranging from 100W to 3000W in power, to cater to diverse industrial applications.

BOGONGCNC’s laser cleaning machine collection includes:

- Portable Models: Compact and lightweight, these portable laser cleaners are ideal for on-site cleaning and maintenance tasks.

- Backpack-Style Machines: Designed for enhanced mobility, the backpack-type laser cleaners enable operators to access hard-to-reach areas with ease.

- Trolley-Mounted Units: These wheeled laser cleaning machines provide a stable and maneuverable solution for larger-scale cleaning projects.

With this versatile product portfolio, BOGONGCNC ensures that customers can find the perfect laser cleaning solution to meet their specific requirements, whether it’s for small workshops or large-scale industrial facilities.

BOGONGCNC’s commitment to innovation and quality has made the company a trusted partner for customers across diverse industries, including automotive, aerospace, manufacturing, and more. By continuously investing in research and development, BOGONGCNC remains at the forefront of laser cleaning technology, delivering advanced solutions that enhance productivity, efficiency, and cost-effectiveness for its clients.

-

Pick Your Best Backpack Laser Cleaning Machine of 2024$5,990.00 – $6,780.00

Pick Your Best Backpack Laser Cleaning Machine of 2024$5,990.00 – $6,780.00 -

Top Rated Portable Laser Paint Stripping Machine for Sale$5,990.00 – $6,990.00

Top Rated Portable Laser Paint Stripping Machine for Sale$5,990.00 – $6,990.00 -

Fiber Laser Cleaning Machine 300w Pulse Laser Cleaning Machine$5,400.00 – $7,800.00

Fiber Laser Cleaning Machine 300w Pulse Laser Cleaning Machine$5,400.00 – $7,800.00 -

Portable 500W Pulse Laser Rust Remover: The Best Choice For Efficient Cleaning And Easy Rust Removal$22,000.00 – $22,500.00

Portable 500W Pulse Laser Rust Remover: The Best Choice For Efficient Cleaning And Easy Rust Removal$22,000.00 – $22,500.00 -

Limpeza com mochila laser: máquina de limpeza portátil | Máquina de limpeza a laser 100W 200W 300W$8,200.00 – $8,500.00

Limpeza com mochila laser: máquina de limpeza portátil | Máquina de limpeza a laser 100W 200W 300W$8,200.00 – $8,500.00 -

máquina portátil da limpeza do laser de 100W 200W 500W com a arma da remoção de oxidação do metal do laser$10,300.00 – $10,600.00

máquina portátil da limpeza do laser de 100W 200W 500W com a arma da remoção de oxidação do metal do laser$10,300.00 – $10,600.00 -

Máquina de limpeza a laser portátil 200W 300W Máquina de limpeza de pintura com ferrugem para venda$5,990.00 – $8,500.00

Máquina de limpeza a laser portátil 200W 300W Máquina de limpeza de pintura com ferrugem para venda$5,990.00 – $8,500.00 -

máquina de limpeza a laser portátil portátil de 100w 200w$5,990.00 – $6,990.00

máquina de limpeza a laser portátil portátil de 100w 200w$5,990.00 – $6,990.00 -

Máquina de limpeza a laser com ferrugem para pintura, 100w, 200w, 300w e 500w$11,150.00 – $28,000.00

Máquina de limpeza a laser com ferrugem para pintura, 100w, 200w, 300w e 500w$11,150.00 – $28,000.00