10 factors to consider when choosing a laser marking machine

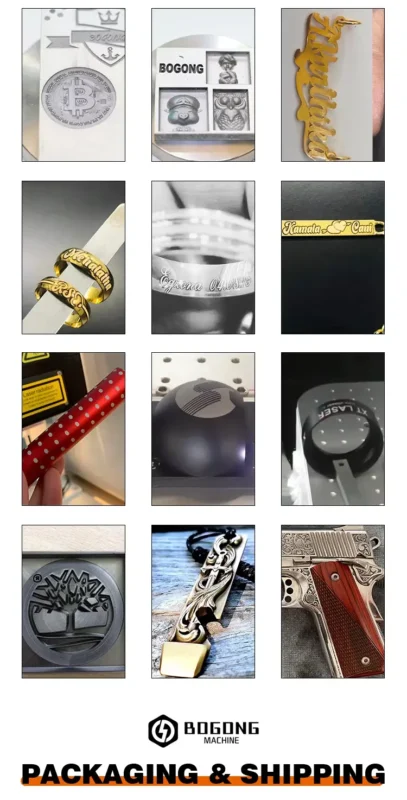

Laser marking machines are a convenient tool for modern manufacturing. You may find it in a wide range of applications.

In modern manufacturing, laser engraving machines are used for product marking. People also use this machine to mark logos, signs, and decorative items. Even for some DIY projects, laser marking and engraving machines are very convenient.

Laser marking machines can accurately engrave on a variety of materials. You can even engrave high-resolution images on wood, plastic or metal.

Please note that the quality of the engraving usually comes from quality laser equipment. Therefore, choosing the right equipment for your project is crucial.

10 factors to consider when choosing a laser marking machine

If you choose the right laser tool, you can get the best etching results and work faster. Additionally, the right laser etching machine can provide versatility. You can use all common types of materials.

Additionally, investing in the right laser equipment ensures long-term returns. Note that a reputable manufacturer is crucial for this. However, the following ten factors can help you choose the right laser equipment.

1.Laser light source

The choice of laser light source is crucial in laser marking. Each laser source type has unique features that make it ideal for specific uses. Understanding these differences can help you choose the right laser marking machine.

Fiber laser marking machine

A fiber laser marking machine generates a laser beam through an optical fiber. These laser devices are suitable for marking a variety of materials.

If you are looking for a metal laser marking machine, fiber laser is the ideal choice.

UV laser marking machine

A UV laser marking machine uses ultraviolet laser beam for marking operations. These laser devices are suitable for ultra-fine marking applications. Typical examples are electronics, leather, food packaging and wires.

CO2 laser marking machine

A carbon dioxide laser marking machine uses CO2 laser as energy source. These laser devices are also suitable for marking a variety of materials.

If you are looking for a wood laser marking machine, a CO2 laser is the ideal choice. It is also suitable for marking wood, paper, leather and fabric.

MOPA laser marking machine

MOPA laser marking machine uses MOPA technology as laser energy. These laser devices provide improved control over marking parameters.

These laser machines are great for color marking. They are also used for darkening, whitening and removing layers.

2.Marking Area

Marking area is a key factor when selecting laser equipment. It is a specific area on the material where the laser marking process takes place. A typical laser marking machine usually has a marking area of 110 mm2 to 300 mm2.

You can check the specs of your machine to see how large your marking area will be. To understand which option is best, you must first evaluate your projected application.

Know the maximum size of your product. Then, find the marked area that works best for you.

3.Marking speed

Another important aspect to consider is marking speed. High-end and low-end types are very different. Speed has a huge impact on overall workflow, productivity and efficiency.

The faster the marking speed, the higher the output. This allows more products to be produced in the same amount of time, which is particularly important in areas with high demand for goods.

Marking speed usually depends on the material type and mark size. Note that laser annealing may take longer than etching. But it ensures the mark is long-lasting and won’t damage the surface.

4.single-mode or multi-mode laser

Single-mode lasers produce a beam of single wavelength. These beams are usually of very good quality and consistency.

This generally means that you can use them to make very accurate and detailed markings. These types of lasers are often used to engrave complex shapes. People also like to use them to mark small parts with high resolution.

Multimode lasers, on the other hand, produce multiple wavelengths. They offer a variety of marking effects.

These lasers are ideal for use with unique surface textures. Color coding on different kinds of products is also common.

5.Marking Materials

Laser marking machines can be used on a variety of materials. Metal, clay, glass, wood, leather, paper, cardboard, fabric and rubber are popular choices.

Different types of laser light sources are suitable for specific materials. For example, fiber lasers are great for metal marking. However, fiber lasers can also engrave other materials. CO2 lasers are great for wood.

UV lasers, on the other hand, are great for ultra-fine applications. They are perfect for wires, gadgets, leather and food packaging. MOPA lasers can mark color, black and white on a variety of materials.

6. Tag Type

There are many methods of laser marking, each with unique advantages. These methods are known for their accuracy and effectiveness.

Laser engravers remove material from surfaces. It often leaves a deep and permanent mark.

Laser etching often changes the surface of the material. It usually creates a contrast between the marked area and the surrounding surface. This method is especially suitable for glass marking.

Layer removal refers to the removal of one or more layers of material. It will continue deleting layers until a contrasting layer appears. This is also called ablation.

Carbon migration is another popular method for marking using lasers. This method usually changes the color of the surface. Typical examples are black marks on stainless steel or titanium.

Another popular method of laser marking is laser bonding. As the name suggests, this method creates a bond between the marking material and the object’s surface.

Now it is obvious that different laser marking machines follow other technologies. Because of this, the type of mark needs to be considered when choosing a laser marking machine.

7.Software suitability

Software compatibility is critical for many reasons. This ensures that the program and machine can work together without any problems. In general, it makes communication and operations easier.

It is also crucial that the machine drivers you use are compatible with the system running on your PC. It checks whether the software can handle and manage the marking process well.

Additionally, advanced software may allow you to change the design and parameters. It allows you to work on multiple files at the same time, making your work more efficient.

As you can see, software plays a vital role in the outcome of your laser marking job.

8.Maintenance and Customer Support

Buyer support is one of the most important things to consider.

Imagine this! You need help from the laser manufacturer, but you can’t contact them. Even if you manage to get in touch, the communication is unclear. This can be frustrating at times because you probably don’t want to pay a lot of money for some stupid machine problem.

To avoid this, it’s crucial to prioritize customer service before making a purchase. Taking this factor into consideration ensures you receive prompt assistance and clear communication. If you have any questions, you can get reliable guidance.

9.Security considerations

There are some risks associated with using lasers. If not handled properly, laser beams can damage your eyes, burn your skin, or even cause fires. Safety is another important consideration when choosing a laser marking machine. You can find out if your machine complies with industry safety and legal rules.

Check the device’s safety features. In this case, you can also seek professional assistance. Learn more about safety precautions during laser marking operations.

10.Budget

When you set a budget for your laser marking machine, don’t factor in the upfront costs. You also have to think long term. Consider total ownership cost (TOC) and operating costs.

Indeed, the initial price is important, but so is accounting for maintenance, repairs and consumables over time.

Investing in a higher-quality machine may mean more upfront costs, but it can save you money in the long run. Why? Because best-in-class machines typically require less maintenance and less downtime. So while you pay more initially, you’re likely to spend less over the life of the machine.

Summarize

Let’s wrap it all up! The above ten factors should be considered when choosing a laser marking machine.

Factor 1 highlights how the choice of laser light source affects accuracy and quality. However, your needs (as shown in factor 2) should guide your choice of marking area.

According to factor 3, marking speed has a direct impact on output. Factor 4, on the other hand, indicates that the marking job will determine whether single-mode laser marking or multi-mode laser marking is best.

Factor 5 determines compatibility and suitability for a specific substrate. On the other hand, factor 6 shows that the type of laser project also affects which laser equipment is best. Factor 7 shows the importance of software to the results.

Find a company you can trust. As discussed in Factor 8, this is necessary for reliable customer service.

However, factors 9 and 10 discuss the need to consider safety and budget.

Overall, this is a great guide to help you choose the right equipment for your project. For more information, please feel free to contact our customer support team. We have a team of professionals who are always happy to assist you.