Air-Cooled Portable Laser Welder with Handheld Welding Gun

$4,500.00 - $8,500.00

Need an affordable welding machine for precision metal joints? Review this beginner-friendly air-cooled portable laser welder with handheld laser welding gun.

1.200 Sets / Month Waiting for Sale In Stock

2.2 Years Limited Warranty for Entire Machine

3.1-2 Days Handling and 7-30 Days Shipping

4.Meet CE Standards in Terms of Quality & Safety

5.30-Day Money Back Guarantee for Your Purchase

6.Online (PayPal) & Offline (T/T, Debit & Credit Cards)

7.Lifetime Free Technical Support for End-Users & Dealers

An air-cooled laser welder is a type of precision welding machine that utilizes a laser to melt metals and join parts together through a focused high-energy beam of light. Unlike water-cooled welding systems that use a cooling fluid to adjust heat dissipation, air-cooled laser welders rely on ambient air for cooling during operation. This design simplifies the machine maintenance, reduces the need for additional components, and allows for more compact setups. Air-cooled laser welding machines are typically favored in applications where portability and ease of use are critical, such as in small workshops or for on-site repairs. They are also popular in industrial uses where precision welding is required, such as in the automotive, aerospace, shipbuilding, and electronics industries.

Features

Portability

The air-cooled handheld laser welder features a compact and lightweight design, making it extremely portable.

Flexible Fiber Optic Cable

The laser beam is delivered to the workpiece using a fiber optic cable. The fiber optic cable is flexible and easy to move, allowing the laser beam to be directed precisely where it is needed.

Adjustable Focus

The laser beam is focused to a very small point, allowing for high-precision welding. The focus can also be adjusted to different depths, allowing for welding of materials of varying thicknesses.

Easy Operation

The mart control panel comes with a user-friendly interface for quick and simple adjustments, allowing users to manage their welding projects in a single setup..

Versatile

Copper nozzles for different welding needs are designed to provide greater flexibility to meet a variety of welding angles, materials, and effects.

Technical Parameters

|

INTERIORINPUT POWER: |

5KW |

|

OUTPUT POWER: |

1500W(800W/1000W/1200W :choosable) |

|

LASER WAVE LENGTH: |

1080nm |

|

LASER: |

MAX |

|

REPEAT FREQUENCY RATE: |

1–10000KHZ |

| WELDING LIGHT CLASS: |

1–5mm |

| CAPACITY CONTROL: |

10—100% |

| WELDING FOCAL LENGTH: |

F=120mm |

| OUTPUT POWER STABILITY: |

<3% |

|

LANGUAGE: |

China, America, Russia, West, Poland,Greece, South Korea, Japan(customizable) |

|

HANDHELD LENGTH: |

10M |

|

WORKING VOLTAGE: |

AC220V士10% 50HZ |

|

WELDING STICK: |

1.0/1.2/1.6 mm |

| COOLING-DOWN METHOD: |

air patenting |

| MACHINE SIZE WEIGHT : |

320*580*580mm55KG |

| SIZE AND WEIGHT OF WIRE FEEDER: |

520*260*450mm 17KG(Contains a 5 KG welding wire) |

| PACKAGE SIZE AND WEIGHT: |

740*510*1030mm 95KG |

Accessories display

Fiber Laser Generator

The best laser generator with independent intellectual property rights.

Low power consumption, maintenance-free, easy assembly, making it a perfect laser source for industrial laser welding, cutting and cleaning.

Laser Welding Gun

Lightweight and easy to use.

The laser welding gun adopts double protective lenses, and the inner lens is designed to be pulled out, which is easy to replace and the product is stable and reliable.

Controller

Humanized operation panel, hand touch control, full functions, including welding, cleaning, cutting working modes, dedicated laser source data monitoring page, technical information, support for more than 20 languages, to meet more customer needs.

Automatic Wire Feeder

When the welding gap is large or a stronger welding strength is required, a wire feeding device is required.

• 0.8/1.0/1.2/1.6 and other specifications of welding wire can be used.

• The wire feeding speed is adjustable, convenient and fast.

Applications & Uses

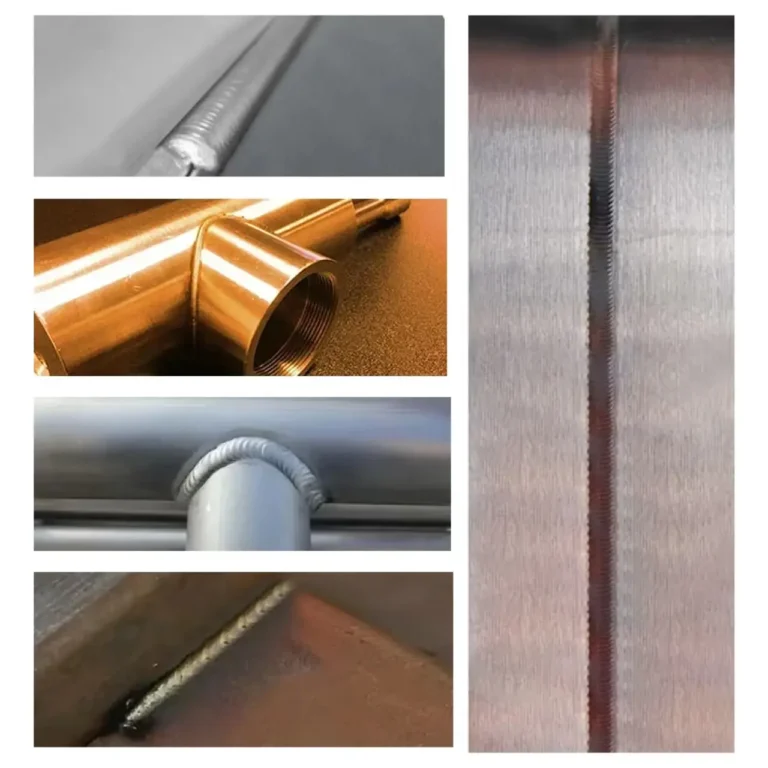

Air-cooled fiber lasers can weld a variety of metals, including but not limited to stainless steel, carbon steel, aluminum, titanium, copper, and nickel alloys. The final process and effectiveness depend on the specific metal properties, thickness, and joint type.

Air-cooled laser welding machines are used in complex and irregular welding processes in industries such as cabinets, kitchens, stair elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, and stainless steel home furnishings.

Projects

Air-cooled laser welders can be performed at various angles, making it versatile for different metal joint types, including Butt, Lap, Corner, Tee, Edge Joints. The flexibility in positioning allows for effective welding of complex shapes and profiles.

レビュー

レビューはまだありません。